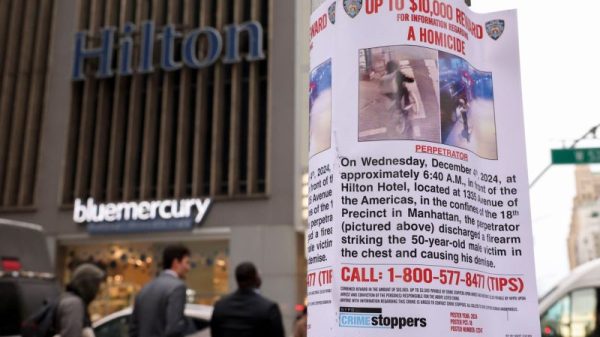

In a recent surprising turn of events, the Federal Aviation Administration (FAA) has raised concerns about the possibility of Boeing and Airbus using counterfeit titanium components in their airplanes. The aviation industry relies heavily on the strength and durability of titanium for critical components in aircraft construction. However, the FAA’s warning about potential counterfeit titanium parts being incorporated into commercial airplanes has raised alarm bells across the industry.

Counterfeit parts in the aviation sector pose significant risks to safety and reliability. Given the stringent quality standards required for aircraft manufacturing, any compromise in material integrity can have catastrophic consequences. Titanium is a crucial material used in aircraft components due to its lightweight properties, high strength-to-weight ratio, and corrosion resistance. Any deviation from the specifications of genuine titanium can compromise the structural integrity of the aircraft.

The potential use of counterfeit titanium in Boeing and Airbus planes underscores the challenges faced by manufacturers in ensuring the authenticity of components throughout the supply chain. The complex and global nature of the aerospace industry makes it susceptible to the infiltration of counterfeit parts, posing a serious threat to aviation safety.

The FAA’s warning serves as a wake-up call for both manufacturers and regulatory bodies to strengthen their processes for detecting and preventing the use of counterfeit materials in aircraft production. Rigorous quality control measures, enhanced supply chain transparency, and collaboration with trusted suppliers are critical steps in safeguarding the integrity of aerospace components.

Furthermore, the investigation into the alleged use of counterfeit titanium in Boeing and Airbus planes highlights the need for robust regulatory oversight and enforcement mechanisms. Regulatory bodies must work closely with manufacturers to conduct thorough inspections, audits, and tests to ensure compliance with quality standards and mitigate the risks associated with counterfeit parts.

The aviation industry’s commitment to safety and quality demands a zero-tolerance approach towards the use of counterfeit materials in aircraft manufacturing. Stakeholders must prioritize transparency, accountability, and diligence in order to maintain the highest standards of safety and reliability in commercial aviation.

As the investigation into the potential use of counterfeit titanium unfolds, it is imperative for Boeing, Airbus, and other industry stakeholders to collaborate closely with regulatory authorities to address any lapses in quality control and restore public trust in the safety of commercial airplanes. The integrity of aircraft components is non-negotiable, and any compromise in this regard must be swiftly rectified to uphold the highest standards of safety in the aviation industry.

The FAA’s warning about the possible use of counterfeit titanium in Boeing and Airbus planes underscores the ongoing challenges faced by the aerospace industry in combating counterfeit parts and ensuring the safety and reliability of commercial airplanes. This development serves as a timely reminder for manufacturers, regulators, and suppliers to remain vigilant and proactive in safeguarding the integrity of aircraft components and upholding the highest standards of quality and safety in aviation.